Aqueous dispersion systems are most commonly used, and they can typically be employed to analyze the relationship between surfactant structure and dispersibility. As hydrophobic solid particles, they can adsorb the hydrophobic groups of surfactants. In the case of anionic surfactants, the outward-facing hydrophilic groups repel each other due to their identical charges. It is evident that the adsorption efficiency of surfactants increases with the length of the hydrophobic chain, and thus surfactants with longer carbon chains exhibit better dispersibility than those with shorter chains.

Increasing the hydrophilicity of surfactants tends to enhance their solubility in water, thereby reducing their adsorption on the particle surface. This effect becomes more pronounced when the interaction force between the surfactant and particles is weak. For example, in the preparation of aqueous dye dispersion systems, highly sulfonated lignosulfonate dispersants can be used for strongly hydrophobic dyes to form dispersion systems with excellent thermal stability. However, applying the same dispersant to hydrophilic dyes results in poor thermal stability; in contrast, using lignosulfonate dispersants with a lower degree of sulfonation yields dispersion systems with good thermal stability. The reason for this is that highly sulfonated dispersants have high solubility at elevated temperatures, causing them to readily detach from the surface of hydrophilic dyes, where the original interaction is already weak, thus reducing dispersibility.

If the dispersed particles themselves carry electric charges and a surfactant with opposite charges is selected, flocculation may occur before the charges on the particles are neutralized. Only after a second layer of surfactant is adsorbed onto the charge-neutralized particles can stable dispersion be achieved. If a surfactant with identical charges is selected, the adsorption of the surfactant onto the particles becomes difficult; similarly, sufficient adsorption to stabilize the dispersion is only achieved at high concentrations. In practice, the ionic dispersants used usually contain multiple ionic groups distributedacross the entire surfactant molecule, while their hydrophobic groups consist of unsaturated hydrocarbon chains with polar groups such as aromatic rings or ether bonds.

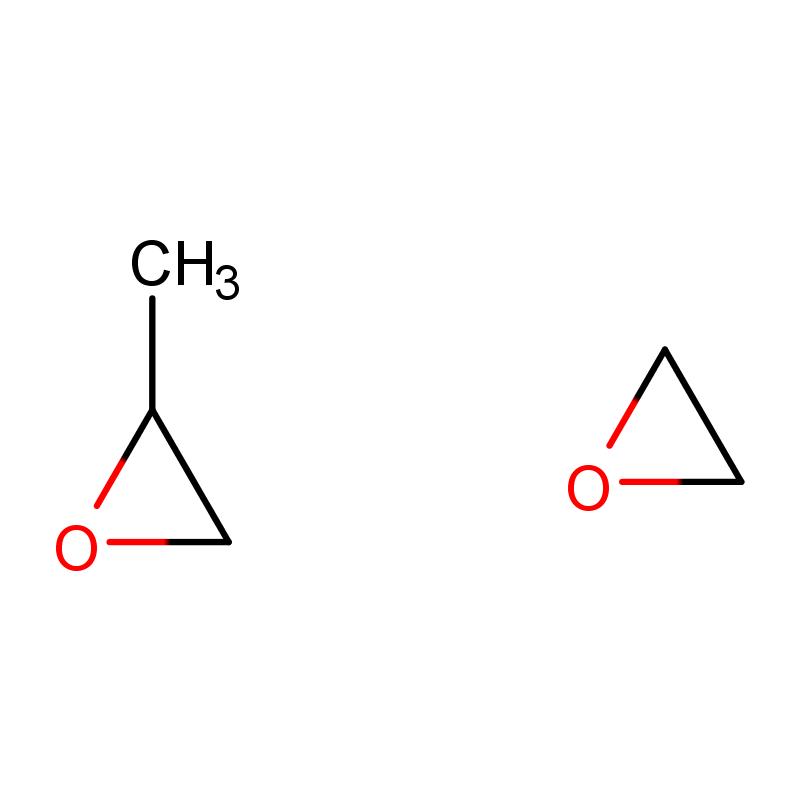

For polyoxyethylene nonionic surfactants, the highly hydrated polyoxyethylene chains extend into the aqueous phase in a curled conformation, creating an effective steric barrier against the aggregation of solid particles. Meanwhile, the thick, multi-layered hydrated oxyethylene chains significantly reduce the van der Waals forces between particles, making them excellent dispersants. Block copolymers of propylene oxide and ethylene oxide are particularly suitable for use as dispersants. Their long polyoxyethylene chains enhance solubility in water, while their extended polypropylene oxide hydrophobic groups promote stronger adsorption onto solid particles; therefore, copolymers with long chains of both components are highly ideal as dispersants.

When ionic and nonionic surfactants are combined, the mixed system not only enables the molecules to extend into the aqueous phase, forming a steric barrier that prevents particle aggregation, but also enhances the strength of the interfacial film on the solid particles. Thus, for the mixed system, as long as the increased solubility of the surfactants in the aqueous phase does not significantly inhibit their adsorption on the particle surface, the dispersant with longer hydrophobic chains will exhibit superior dispersing performance.

Post time: Dec-31-2025