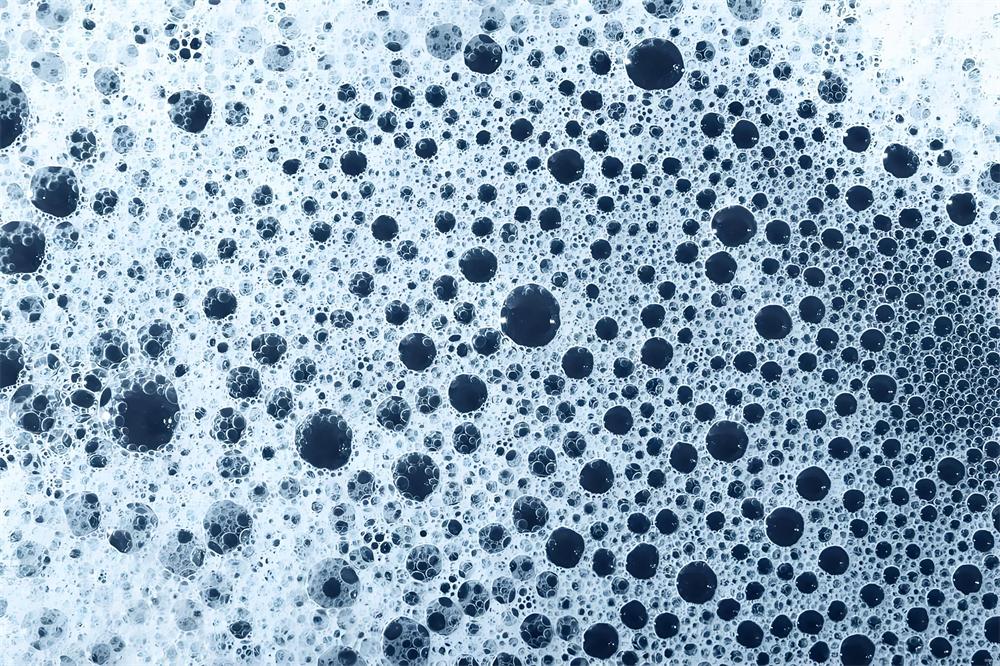

When air enters a liquid, since it is insoluble in water, it gets divided into numerous bubbles by the liquid under external force, forming an heterogeneous system. Once air enters the liquid and forms foam, the contact area between gas and liquid increases, and the free energy of the system also rises accordingly.

The lowest point corresponds to what we commonly refer to as the critical micelle concentration (CMC). Therefore, when the surfactant concentration reaches the CMC, there are a sufficient number of surfactant molecules in the system to densely align on the liquid surface, forming a gap-free monomolecular film layer. This minimizes the system’s surface tension. When the surface tension decreases, the free energy required for foam generation in the system also reduces, making foam formation much easier.

In practical production and application, to ensure the stability of prepared emulsions during storage, the surfactant concentration is often adjusted above the critical micelle concentration. While this enhances emulsion stability, it also has certain drawbacks. Excessive surfactants not only minimize the system’s surface tension but also envelop the air entering the emulsion, forming a relatively rigid liquid film, and on the liquid surface, a bilayer molecular film. This significantly hinders foam collapse.

Foam is an aggregation of many bubbles, whereas a bubble is formed when gas is dispersed in a liquid—gas as the dispersed phase and liquid as the continuous phase. The gas inside bubbles may migrate from one bubble to another or escape into the surrounding atmosphere, leading to bubble coalescence and disappearance.

For pure water or surfactants alone, due to their relatively uniform composition, the resulting foam film lacks elasticity, making the foam unstable and prone to self-elimination. Thermodynamic theory suggests that foam generated in pure liquids is temporary and dissipates due to film drainage.

As mentioned earlier, in water-based coatings, besides the dispersion medium (water), there are also emulsifiersfor polymer emulsification, along with dispersants, wetting agents, thickeners, and other surfactant-based coating additives. Since these substances coexist in the same system, foam formation is highly likely, and these surfactant-like components further stabilize the generated foam.

When ionic surfactants are used as emulsifiers, the bubble film acquires an electrical charge. Due to strong repulsion between charges, bubbles resist aggregation, suppressing the process of small bubbles merging into larger ones and then collapsing. Consequently, this inhibits foam elimination and stabilizes the foam.

Post time: Nov-06-2025