1.Emulsifying Effect

The comprehensive affinity of the hydrophilic and lipophilic groups in surfactant molecules for oil or water. Based on experience, the range of the Hydrophilic-Lipophilic Balance (HLB) value of surfactants is limited to 0–40, while that of non-ionic surfactants falls within 0–20.

Mixing additivity formula:HLB=(HLBa Wa+HLBb /Wb) / (Wa+Wb)Theoretical Calculation:HLB=∑(HLB Value of Hydrophilic Groups)+∑(HLB Value of Lipophilic Groups)-7 HLB:3-8 W/O-type Emulsifier:Tween;HLB Value of Monovalent Soaps:8-16 O/W-type Emulsifier:Span;Divalent Soaps.

A coarse dispersion system formed by dispersing one or more liquids as liquid droplets with a diameter greater than 10−7m in another immiscible liquid is called an emulsion. An emulsifier must be added to maintain its stable existence. Depending on the structure of the emulsifier, it can form either an oil-in-water (O/W) emulsion with water as the continuous phase or a water-in-oil (W/O) emulsion with oil as the continuous phase.Sometimes, another type of surfactant needs to be added to break the emulsion, which is called a demulsifier. It separates the dispersed phase from the dispersion medium in the emulsion. For example, demulsifiers are added to crude oil to separate oil from water.

2.Foaming and defoaming effects

Surfactants are also widely used in the pharmaceutical industry. In pharmaceutical preparations, many water-insoluble drugs such as some volatile oils, fat-soluble celluloses and steroid hormones can form transparent solutions and increase their concentrations by virtue of the solubilization effect of surfactants. In the process of pharmaceutical preparation, surfactants serve as indispensable emulsifiers, wetting agents, suspending agents, foaming agents and defoamers. A “foam” is defined as a gas enclosed by a liquid film. Certain surfactants can form films of a certain strength when mixed with water, which trap air to generate foams; such surfactants are called foaming agents and are applied in froth flotation, foam fire extinguishing and cleaning & stain removal. On the contrary, defoamers are also needed in some scenarios: for example, excessive foams are generated during sugar production and traditional Chinese medicine processing, so appropriate surfactants should be added to reduce the strength of the liquid film, eliminate the bubbles and prevent accidents.

3.Suspending effect

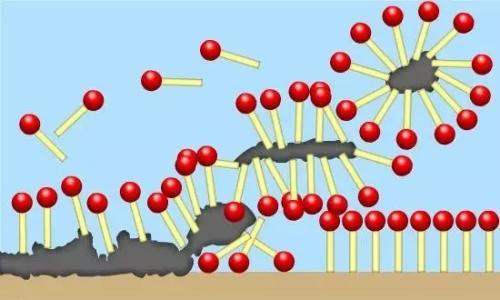

In the pesticide industry,a certain amount of surfactants is required for wettable powders, emulsifiable concentrates, and concentrated emulsions. For instance, the active ingredients in wettable powders are mostly organic compounds with hydrophobicity. Only in the presence of surfactants, which reduce the surface tension of water, can the pesticide particles be wetted by water and form aqueous suspensions.

The application of surfactants in ore flotation relies on the flotation-aiding effect. The ore pulp is stirred while air is blown from the bottom of the tank; bubbles carrying effective ore particles then gather on the surface. These bubbles are collected, and the foam is broken and concentrated to achieve the purpose of ore enrichment. The ore-free silt and rock remain at the bottom of the tank and are removed regularly. When 5% of the ore particle surface is covered by collectors, the surface becomes hydrophobic, causing the ore particles to attach to the bubbles and float up to the liquid surface for easy collection. Suitable collectors should be selected such that their hydrophilic groups are adsorbed only on the ore particle surface, with the hydrophobic groups oriented toward the water.

4.Disinfection and sterilization

In the pharmaceutical industry, they can be used as fungicides and disinfectants. Their bactericidal and disinfectant effects are attributed to their strong interaction with proteins in bacterial biofilms, which denatures or disables these proteins. These disinfectants have relatively high solubility in water. Depending on the concentration used, they can be applied to preoperative skin disinfection, wound or mucosal disinfection, instrument disinfection, and environmental disinfection.

5.Detergent and cleaning effect

Removing greasy dirt is a relatively complex process, which is related to the above-mentioned functions such as wetting and foaming. Detergents usually need to add a variety of auxiliary ingredients to enhance the wetting effect on the objects to be cleaned, and also have functions such as foaming, whitening, and occupying the cleaned surface to prevent re-contamination. Among them, the decontamination process of surfactants, which are the main components, is as follows: water has high surface tension and poor wetting performance on oil stains, making it difficult to wash off oil stains. After adding surfactants, the hydrophobic groups face the fabric surface and adsorb on the dirt, causing the dirt to gradually detach from the surface. The dirt is suspended in water or floats to the surface with the foam and then removed, and the clean surface is occupied by surfactant molecules. Finally, it should be noted that the function of surfactants is not only due to one aspect of their role; in many cases, it is the result of the combined action of multiple factors. For example, in the papermaking industry, they can be used as cooking agents, waste paper deinking agents, sizing agents, resin barrier control agents, defoamers, softeners, antistatic agents, scale inhibitors, softeners, degreasers, bactericides and algaecides, corrosion inhibitors, etc.

Post time: Dec-29-2025